Testing & Defect Resolution

Rail Testing

The UTU’s rail profile scanner uses laser technology to compare the state of the railhead with a pre-programmed template to judge if the track is becoming worn out of shape, and in need of grinding.

UTU trains do not replace traditional track walks by track testing staff – although they do reduce the need for them. Instead, they direct the focus of track walks to areas needing inspection, saving time and money, and increasing the safety of the network.

TES staff undertake the role as an Ultrasonic Rail Flaw Detector Operator (URFDO) and operates a manual piece of rail flaw equipment, such as a B Scan stick (portable test process). The operator pushes a mobile test device over one rail individually or both rails simultaneously (at a walking pace) while visually interpreting test data on a monitor and ranking the flaw and reporting back to the relevant Rail Maintenance teams on the findings.

Detecting Defects

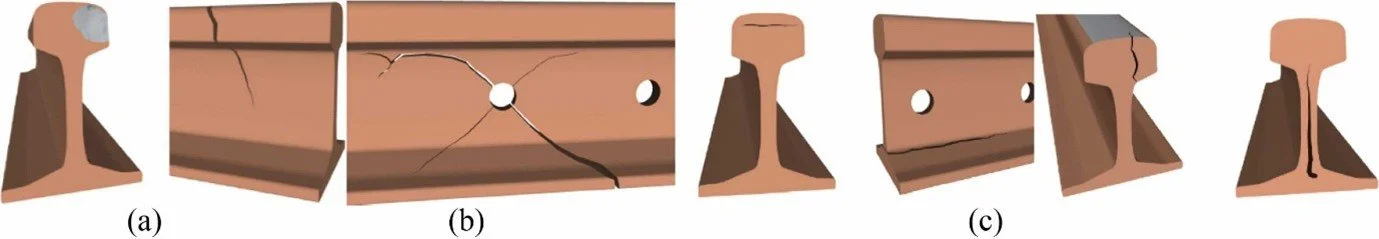

Fig. 1. Internal defects in rail: (a) transverse defects, (b) bolt hole cracks, and (c)

Fig. 2. Rail surface defects: (a) spalls and gauge corner checking, (b) shelling, (c) squats, and (d) wheel burn defect.

Typical service-induced discontinuities that occur in rail sections are head and web separation, horizontal split head, detail fracture, transverse fracture, engine burns, shelling, and bolt hole cracks. Head and web separations, as well as horizontal split heads, can be easily detected using a UT flaw detector with a 2.25 MHz / 0.50 in. straight beam transducer (such as our A106S) positioned over the rail centreline. By observing the returned signal, head and web separations can be confirmed through the loss of the back echo, which represents the reflection of the UT signal off the base of the rail.

Bolt-hole and transverse discontinuities are typically detected using 2.25 MHz / 0.50 in. angle beam transducers (such as the A540S paired with the ABSA-5T-X). Bolt-hole cracks tend to propagate at a 45-degree angle, making them particularly sensitive to detection when using a 45-degree angle beam transducer. Detecting transverse discontinuities and detail fractures, however, requires angle beam transducers with higher refraction angles (typically 60 to 80 degrees). Detectability improves for discontinuities that are angled downward in the same horizontal direction as the flow of heaviest traffic.

Ultrasonic inspection can be split into manual and train borne testing which is carried out by an Ultrasonic Test unit (UTU).

Manual Testing

Over time, rails develop defects originating from either a manufacturing defect or from in-service use. These defects can be disastrous if they go undetected and must be monitored through scheduled maintenance. Today, the majority of rail testing is performed using specially developed rail born trains. Its two separate ground penetrating radar units can detect irregularities in the ballast and formation up to two metres deep, including voids; reporting any negative findings to the Maintainer for remedial action. The ultrasonic test equipment on board can give early warning of any problems that could later occur with the track.

Train Borne Testing

Ultrasonic Rail Flaw detection URFD plays a critical role in rail safety and maintenance of the tracks.

Using high frequency, directional sound waves to measure the material thickness of the rails either by utilising vehicular equipment, such as specially designed trains or manually.

Early Detection of Internal Flaws UT can identify cracks, voids, and inclusions inside the rail that aren’t visible on the surface — especially transverse and longitudinal cracks that can lead to catastrophic failure if undetected.

Meet the Head of Track Services

Graham Eastabrook - Professional Head of Track Services

Graham has been with TES since 2012, with a wealth of experience that only comes with… well… experience. He is a Fellow of the Permanent Way Institute and a Fellow of the Chartered Management Institute. Graham leads all track-related projects.

Contact Us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!

Explore more of TES

Want to explore more of what TES have to offer? Use the search function below